Appendices

Appendix I

Grower resources

Appendix II

Federal import quarantine order for Pseudomomas syringae pv. actinidiae (Psa)

Appendix III

Statewide market analysis methodology and results

Appendix IV

Massachusetts Department of Agriculture (MDAR) decision letter (8/28/17)

Appendix V

Supplement on Actinidia kolomikta

Appendix VI

Areas of needed research

Appendix VII

Effects of harvest time and cold storage on the quality of berries of A. arguta cvs. ‘Ananasnaja’ and ‘Geneva 3’

Appendix VIII

Vineyard tasks, a seasonal timeline

Fig 1

Fig 2

Fig 3

APPENDIX VII

Effects of harvest time and cold-storage on the quality of berries of Actinidia arguta cvs. ‘Ananasnaja’ and ‘Geneva 3’

Research presented at the IX International Kiwifruit Symposium in Porto, Portugal

| *NOTE: Initial reporting of these studies listed the cultivar as ‘Michigan State SVF’ due to sourced nursery tags. Subsequent genetic analysis revealed that, in fact, it was a mixture of ‘Ananasnaja’ and ‘Geneva 3’ berries used in those studies. |

Materials and Methods

A. arguta cvs. ‘Ananasnaja’ (USDA National Plant Germplasm System accession PI617136) and ‘Geneva 3’ (USDA National Plant Germplasm System accession PI 617133) were chosen for this study based on their reliable productivity at the NHAES, relatively large (>6 g average) and uniform berry sizes, attractive appearance, acceptable eating quality, and the existence of a sufficient number of mature vines at the NHAES to provide the quantity of berries required for adequate replication.As per the recommendations outlined in the Harvesting section of the Production Guide, harvest began when a distributed sampling of physiologically mature berries throughout the canopy yielded an average °Brix ≥ 8.0.

During the 2016 growing season, this threshold mean °Brix was achieved on September 19, the date designated “Day 0” in this study; and random samples of 800 berries each were harvested on Days 0, 5, 10, and 15. On each day, the harvested berries were randomly distributed into 80 6 oz. plastic, ventilated clamshells, which were then randomly assigned to a factorial combination of cold storage periods (0, 2, 4, and 6 weeks) and subsequent ripening periods (0, 3, 6, 9, and 12 days) at room temperature (RT; 20°C). In all, there were four independent replications (i.e. clamshells) of each unique combination of harvest time, cold storage duration, and RT ripening period.

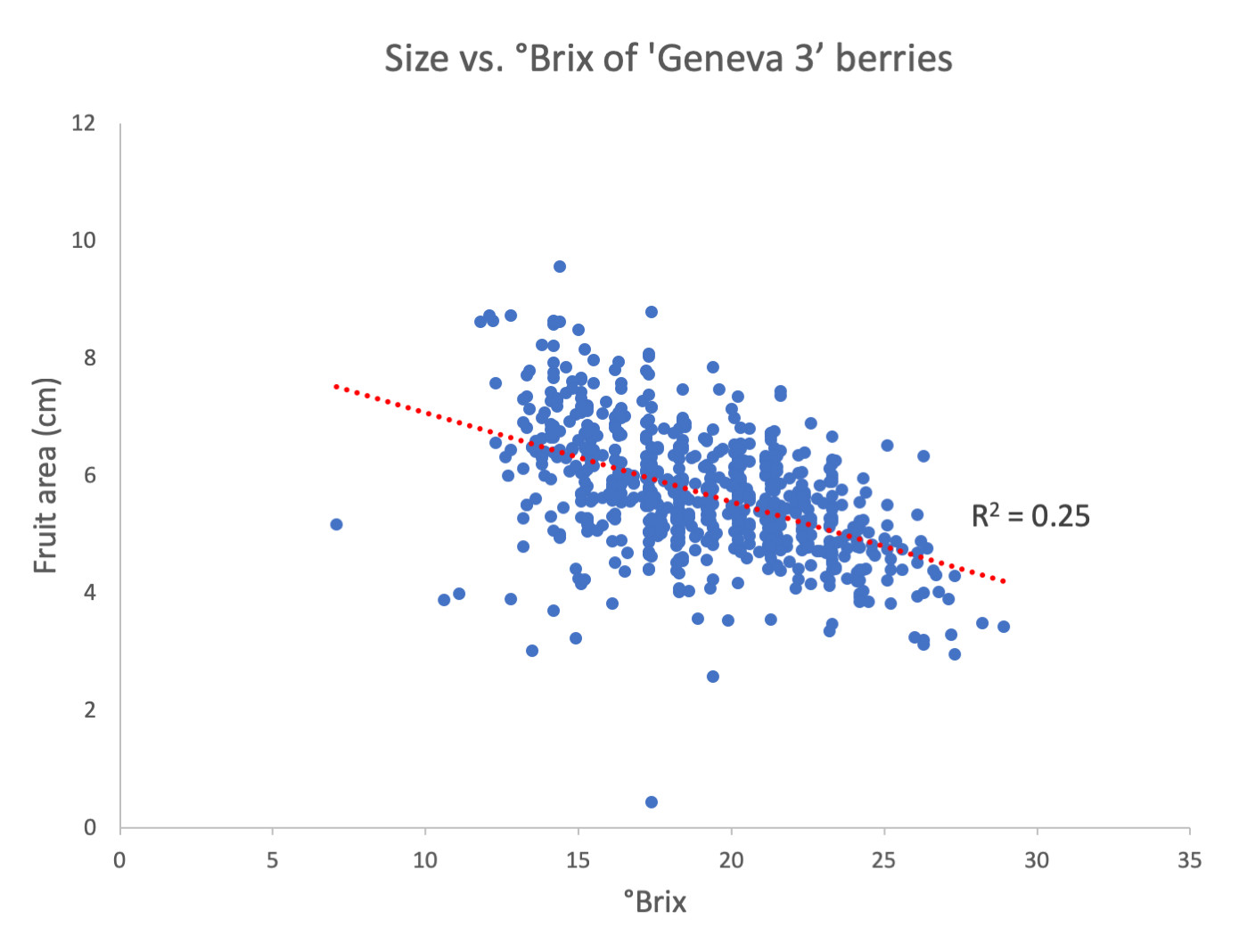

Berry selection When packing the clamshells (10 berries in each), berries which had prematurely softened or were torn at the petiole were discarded, as were those that were misshapen due to poor pollination or were otherwise injured. Berries were not, however, sorted or distributed based on size, as previous research conducted at the NHAES indicated no strong correlation between the size and relative degree of ripeness of berries on a vine (Fig 1).

Cold storage After packing, the clamshells were either moved directly into ripening at RT or, if designated for a period of cold temperature storage (2, 4, or 6 weeks), were placed immediately in a chromatography refrigerator set at 4°C. Temperature was monitored throughout the study and did not fall below 3°C or exceed 5°C. Relative humidity was not monitored or controlled.

Ripening and measurement During the 2015 growing season, we conducted a pilot study in which berry ripening was tracked for 18 days after removal from various durations of cold storage (2, 4, and 6 weeks). Based on the results of that preliminary study (°Brix measurements and informal taste and eating quality observations), it was decided to reduce the extent of post-cold-storage sampling in the current study to only 12 days. On the designated day for quality evaluation, four berries were pulled randomly from the ten in a given clamshell and cut in half via lateral cross-section. °Brix was measured from each of the halves using a handheld refractometer and averaged, with readings exceeding the refractometer’s limit (32°Brix) noted as 32.5°Brix. Photographs were taken for subsequent dimensional analysis (ImageJ software) and visual quality assessment.

Results

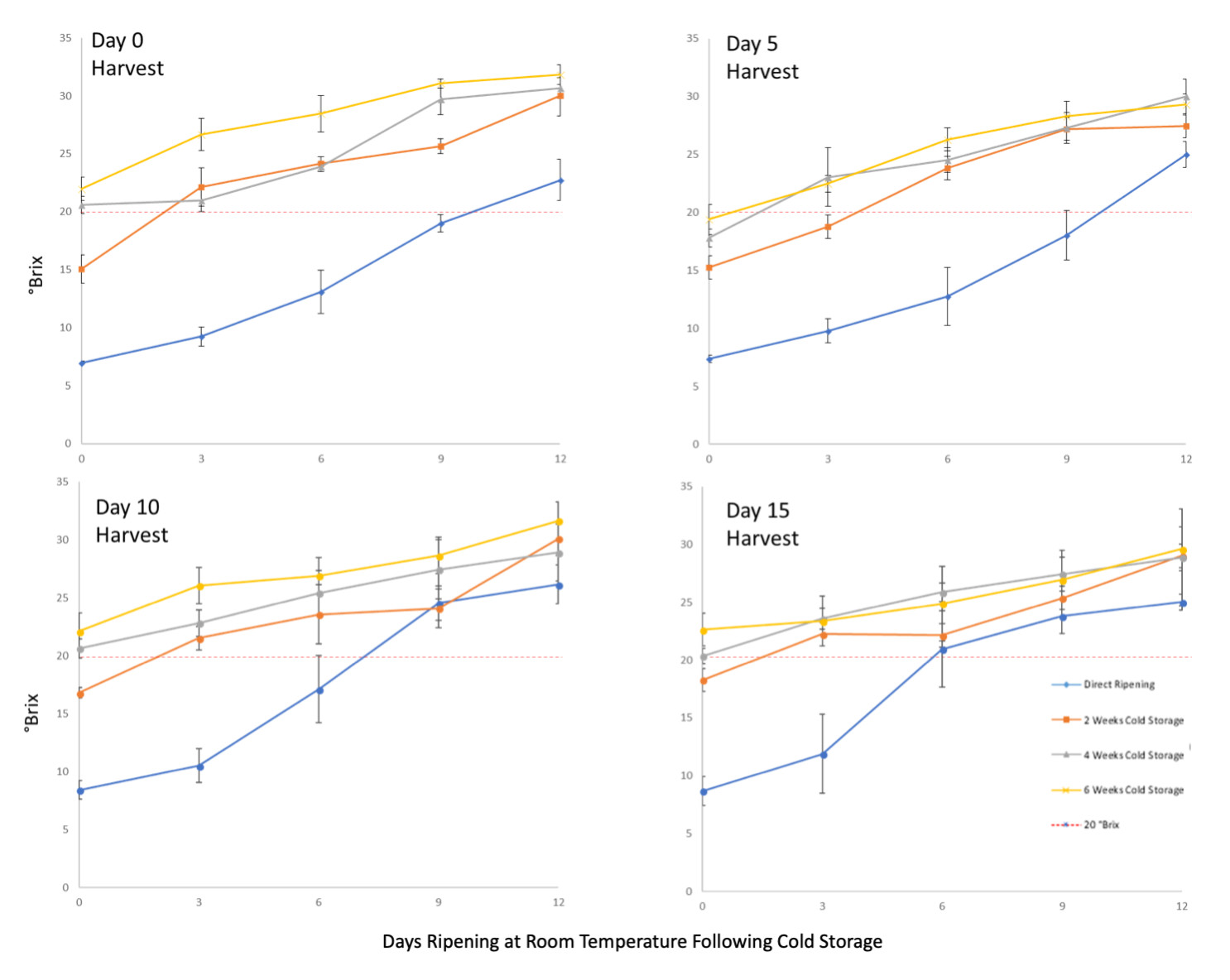

As shown in Fig 2, the peak °Brix achieved by berries harvested on Day 0 (31.9°Brix) was commensurate with the highest levels achieved by berries left to ripen on-vine for an additional 15 days. Indeed, the results consistently indicate that no significant improvement in peak °Brix is realized by leaving berries to continue to ripen on-vine once they reach physiological maturity. There was, however, a difference in peak °Brix accumulation in berries held in cold storage for at least 2 weeks prior to ripening versus those that were directly ripened. Berries held in cold storage were characterized by higher °Brix levels, with the effect more pronounced for earlier harvest times (Days 0 and 5). It is clear from the data, however, that the storage temperature was not low enough to hold the berries in metabolic stasis. Indeed, over the period of 6 weeks in cold storage, the mean sugar levels of Day 0 berries rose from 8.0 to 22.0°Brix, while those of Day 15 berries rose from 8.7 to 22.6°Brix. In general, 2 weeks of cold storage in this study appears to have been roughly equivalent, in terms of ripening, to 6-9 days at RT. Because of this ongoing ripening under cold storage, it is difficult to interpret the differential rates of ripening of berries stored for varying lengths of time.

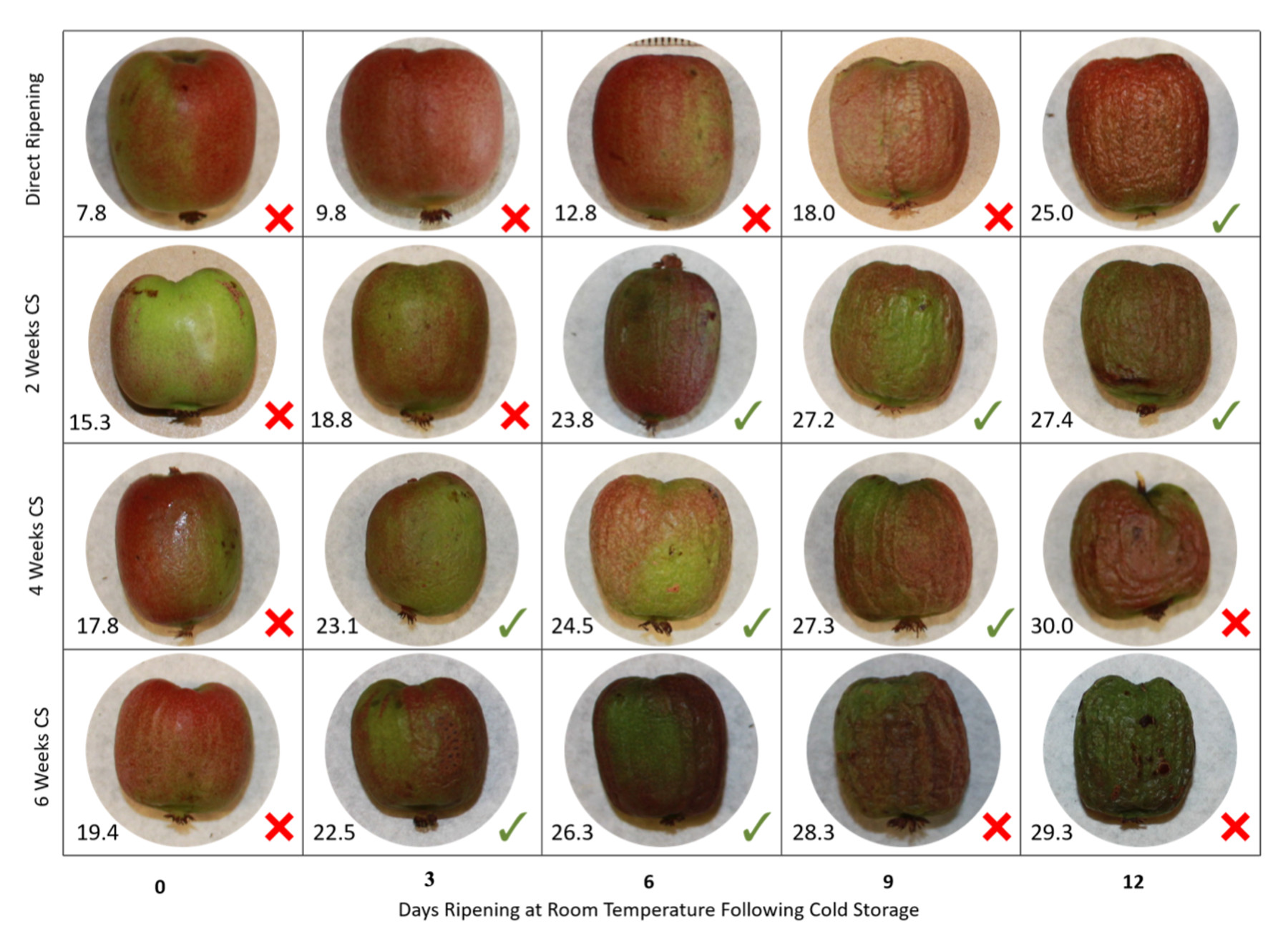

Although ripening rates are difficult to interpret from these data, the berries from all harvests reached the minimum 20°Brix necessary, in our subjective experience, for acceptable eating quality. As shown in Fig 3, our findings also indicate that berries can be held in storage, even at our insufficiently cold temperatures, for up to 6 weeks while remaining marketable. In this assessment of marketability or “eating quality”, we considered not only °Brix but also overall taste, mouthfeel, and appearance (mainly the extent of discoloration and/or wrinkling due to desiccation). Overall, berries held for longer periods of time in cold storage appear, when ripened, to be of acceptable eating quality for shorter windows of time. For example, Day 5 berries held for 2 weeks in cold storage exhibit acceptable quality for 9 days (Days 3-12) while those held for 4 and 6 weeks do so for only 6 days (Days 3-9).

Figure captions

Fig 1 Intensive sampling of berries from five diverse cultivars of A. arguta (cvs. ‘Chang Bai Mountain 1’, ‘Jumbo’, ‘Ogden Point’, ‘Ananasnaya’, and ‘Geneva 3’) revealed no strong correlation between berry size and °Brix. Data from cv. ‘Geneva 3’ presented.

Fig 2 Plots depicting the effects of harvest date (Days 0, 5, 10, and 15), time in cold storage (0, 2, 4, and 6 weeks), and time at room temperature after cold storage (0, 3, 6, 9, and 12 days) on °Brix level. Harvest Day 0 was September 19, 2016, the day when the mean on-vine °Brix level reached 8.0. A threshold of 20°Brix, subjectively deemed a minimum for acceptable eating quality, is indicated by the red dashed lines. The axes on all four plots are uniform.

Fig 3 Representative images of Day 5 harvest berries from all four cold storage (CS) durations and five room temperature ripening periods. The average °Brix value observed for each CS-ripening combination is shown in the lower left corner of each grid cell. A green check in the bottom right corner indicates that the berries in that treatment were found to be of acceptable “eating quality”, a composite assessment of °Brix level, flavor, mouthfeel, and appearance. A red X indicates unacceptable quality, due to one or more of the traits mentioned.