Harvesting

Harvest indicators

While many small fruit and berry crops signal their ripeness and readiness for harvest with a clear visual indicator like skin color, the majority of kiwiberries do not1; so determining when to harvest requires strategic scouting for less obvious signs. Leaving berries to ripen on-vine is not recommended, as such a practice significantly increases risk of loss due to pests, diseases, harvesting (e.g. tearing) and handling injuries, and fall weather events (see Insect pests, diseases, and other production concerns). Indeed, in commercial kiwiberry production, the goal should be to harvest as early as possible, with the intention of bringing berries to peak ripeness off-vine, following all necessary sorting and packaging. The guidelines in this section assume this mindset.

Beginning in early September, you should begin to sample berries for physiological maturity as an initial harvest indicator approximately every other day at randomized locations throughout the vineyard. Be aware that differences in elevation and microclimates can modulate the progression of berry development within the same farm by as much as two weeks (D. Jackson, pers. communication), so the total number of vines sampled should reflect these factors as well as total vineyard size. As a rule of thumb, one should sample 5-6 vines per variety per acre of production, according to the following protocol:

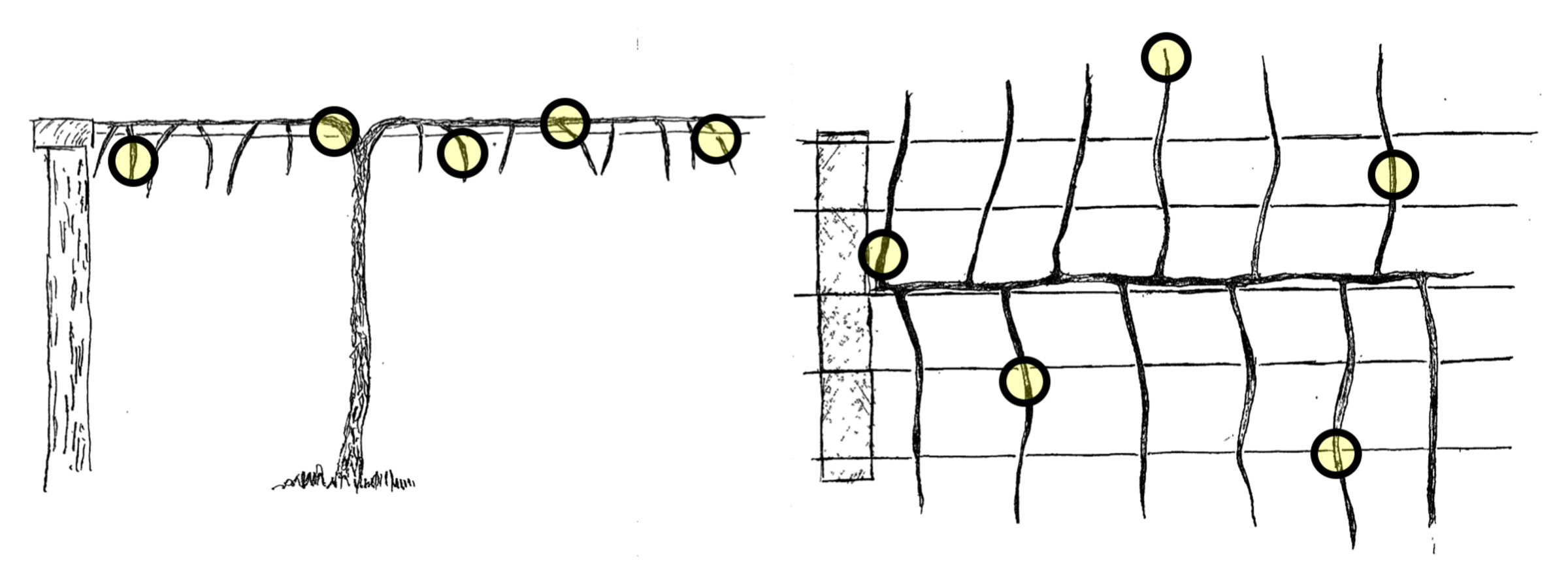

- Select 4-5 berries from throughout the canopy to ensure reliable representation, thus minimizing the risk of an early or late berry skewing results (Fig 41).

- Cut all berries in cross-section and inspect seed color. A kiwiberry has reached physiological maturity once its seeds turn uniformly dark brown/black in color, a condition referred to as “black seed stage” (Fig 42).

Once the vineyard has reached black seed stage, it is nearing time for harvest, meaning a more refined method of assessing harvest readiness is required. Two such methods are described in detail below:

1. Sugar content

An affordable, simple-to-use, and reliable tool for assessing degree of ripeness is a handheld refractometer, an instrument that estimates the total dissolved solids in a liquid (e.g. kiwiberry juice) based on the refraction of light through the sample. Because a high proportion of such soluble solids in fruits are sugars, this measurement of soluble solids concentration (SSC) serves as a reasonable estimate of total sugar content, expressed in units of oBrix (degrees Brix). One unit of oBrix is defined as being equivalent to 1% total sugar content; thus a value of 24oBrix indicates that a liquid sample is roughly 24% sugar.

To ensure that kiwiberries are sufficiently mature to reach desired levels of peak ripeness off-vine (> 20oBrix), harvest should occur between 6-8oBrix. First-time growers should not be concerned by the fact that berries at this stage are very firm and exceedingly unpleasant to eat; for they will continue to ripen post-harvest. When monitoring for progress of oBrix in the field, the same sampling protocol for black seed stage should be followed. In this case, however, the sampled berries should be cut in cross-section and the juice from one half squeezed onto the testing stage of a refractometer for measurement. Harvest can safely begin once the average of the samples lands within the target range of 6-8oBrix.

Note that refractometers should be calibrated daily using a prepared sugar solution in distilled water, cleaned between samples, and operated within their manufacturer-specified temperature ranges. Hand-held refractometers, both optical and digital, are available in a wide range of prices (~$30 to more than $500), with varying levels of sensitivity.

2. Dry matter content

Soluble solids contribute to a berry’s total dry matter; thus percent dry matter (%DM) is correlated to both SSC and sugar content and can serve as an indicator of ripening. More broadly, because %DM takes into account both soluble and insoluble solids, the combination of which influence not only taste but texture, measuring %DM is considered the standard for quality control in fuzzy kiwifruit production (Crisosto et al. 2011).

Provided one has access to an oven and a digital scale with an accuracy of at least 0.5 g (~0.02 oz), monitoring ripening by %DM is straightforward. The same sampling protocol for black seed stage can be followed, ensuring a minimum sample size of 10 berries. After the initial total weight of the sample is taken (WeightInitial), the fruits are cut into thirds, dried at low temperature (maximum 200℉), and re-weighed (WeightFinal). With these two weights, %DM is calculated as:

\(\%DM=\frac{Weight_{Final}}{Weight_{Initial}}\times 100\)

There are advantages and disadvantages of this method relative to using a refractometer. Although the actual process of drying takes time (e.g. overnight), overall the %DM method requires less hands-on time and more easily accommodates large sample sizes. Berries at early stages of ripeness are firm and can be difficult to squeeze for a liquid sample, making the use of refractometers time-intensive. Furthermore, each berry must be measured individually for oBrix and each of these measurements must be recorded, making the processing of large samples tedious. In contrast, cutting berries for drying is quick, even if they are firm; and calculating %DM requires only two weights, regardless of the number of berries in the sample.

The disadvantage of the method lies in the fact that currently no validated, standard %DM has been established as a harvest threshold for kiwiberries. For the variety “Michigan State (SFV),” preliminary investigations in the NHAES program indicate harvest can safely begin once berries reach 20-22% dry matter. It is quite possible, however, that this result is variety (and possibly even vineyard) specific. Growers interested in using the %DM method may wish to monitor their vineyard by both methods (oBrix and %DM) the first few seasons to establish a %DM threshold appropriate to their operations.

Some small-scale growers report that they determine when to harvest based on feeling for the presence of berries that are soft to the touch, something that would indicate a much higher level of SSC relative to the above detection methods (Hassall et al. 2016). There appears to be no standard practice for such an approach, however, with anywhere from 1-10% soft berries initiating harvest. And as argued above, such an on-vine ripening approach unnecessarily increases the risk of loss to pests like the spotted-wing drosophila (D. suzuki), as well as damage from fall weather events, harvesting, and handling. Given these increased risks, this practice is not recommended.

Harvest methods

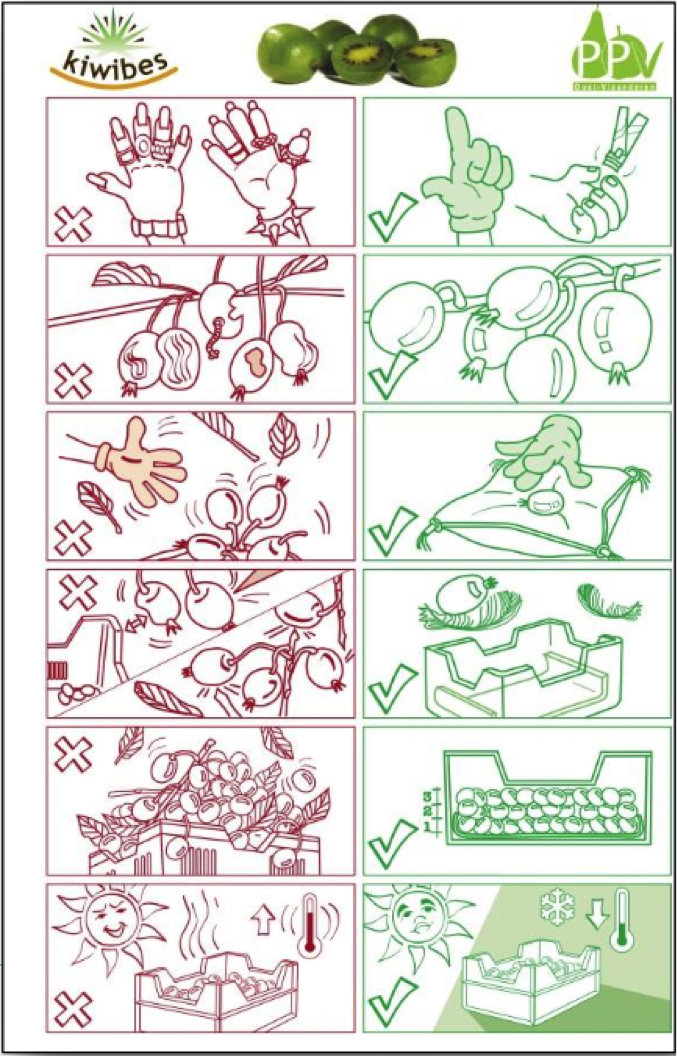

Harvest should commence as soon as the selected harvest indicator is met. Although climacteric kiwiberries can be harvested while firm, greatly reducing the risk of damage during harvest, sorting, and shipping, care should still be taken in their handling. Unnecessary movement or handling should be avoided; and gloves should be worn during harvest to both minimize fruit bruising and support clean handling practices from vine to consumer. Because current varieties are not amenable to whole cluster harvesting and marketing, as is done in grapes, berries must be separated for sorting and packaging. At the NHAES, this separation is accomplished in the field, with individual berries harvested one-by-one into bins. In contrast, a common practice in European production is a two-step harvesting process in which entire spurs are removed from the vineyard, after which individual berries are cut from the clusters on the pack line (P. Latocha, pers. communication).

Once removed from the vine, berries should be limited to a shallow packing depth to reduce crushing damage and to maintain air flow (Fig 43); and harvest containers should be easily cleanable and vented to promote air circulation (Fig 44). To prolong storage life and limit storage disorders, harvest conditions should be such that fruit is free of all excess moisture (dew/rain) before going into storage. In the case of poor weather, in which delaying harvest by a few days could promote better drying before storage, the slight progress in ripening on the vine is more than justified.

Should I sort while harvesting?Due to sanitation concerns as part of a well managed Integrated Pest Management Program, producers are strongly recommended to harvest all berries from the vineyard. Necessary sorting and culling should be done after harvesting (see Postharvest Handling) in such a way that culled/discarded fruit can be properly disposed of rather than left to ripen on the vine. |

1 Although the skin of some cultivars may develop a red blush as they mature, such color development is greatly influenced by exposure to direct sunlight and thus is not a reliable method for harvest maturity.

Fig 41 Schematic of the distribution of locations (circles) within a kiwiberry canopy (Left, profile; Right, aerial) from which berries should be sampled to reliably ascertain fruit maturity.

Fig 42 “Black seed stage” indicates that a kiwiberry has reached physiological maturity.

Fig 43 An excellent infographic of best harvest and handling practices for kiwiberries. Figure credit: Management Strategies for a Productive Kiwiberry Orchard (Debersaques 2017)

Fig 44 Wooden containers (left) are durable but difficult to sanitize. Ventilated plastic lugs (right) are equally as durable, often able to nest within each other, and are easy to sanitize as needed.