Postharvest handling

Kiwiberry breeding is in its infancy, with available varieties being only a few generations from wild plants and in many cases the result of serendipity rather than systematic breeding. One consequence of this state of affairs is that current varieties can at the time of harvest exhibit significant levels of variation, even within an individual vine, in important traits such as berry size and degree of ripeness. Such lack of uniformity in terms of both appearance and maturation presents a challenge to producers and marketers and necessitates significant investment in sorting, storage, and controlled ripening for commercial kiwiberry operations. According to one large-scale producer, sorting alone accounts for ~12% of total annual production costs (D. Jackson, pers. communication) (see Enterprise Analysis).

Sorting and grading

Assuming the objective is to produce high-value berries for fresh-eating, the ability to efficiently sort and grade kiwiberries is essential for the large-scale commercial success of the crop. The few current producers in the region sort their harvests by hand, either bin-by-bin or on a pack line (conveyer belt) (Fig 45), and manually pack the selected berries into containers (e.g. vented clamshells) for storage. This basic approach likely represents the short- to medium-term reality of kiwiberry production in the region, but manual sorting is costly and prone to error. Fortunately, alternative methods exist which should be kept in mind as the sector grows.

As with many global commodity fruits, the fuzzy kiwifruit sector has invested significant resources in developing sophisticated, automated sorting and packing equipment; and available systems for kiwiberries are increasingly being used in Europe and New Zealand. Such systems, like those manufactured by Stas Belgium, rely on near-infrared (NIR) sensors to scan, sort, and cull berries based on a range of both external and internal quality attributes, including size, weight, shape, firmness, color, and degree of cosmetic damage. By providing a level of quality control far beyond what is detectable by the human eye, such systems promote uniformity in berry appearance, ripening, and post-harvest performance, thereby improving overall consumer satisfaction.

While investing in an expensive, automated, NIR-equipped pack line may make little sense for all but the largest commercial operations, the possibility exists to create cooperative pack houses to divide such a capital cost among multiple regional producers. In theory, following this regional food-hub mindset, cost sharing could be extended further if the equipment were versatile enough to process other small fruit crops as well, especially those harvested earlier in the season (e.g. blueberries and cherries). Until such facilities come online, however, innovation will be required to develop low-cost, high-throughput sorting methods for small-scale producers. Further research and innovation is required to address possible low-cost options for fruit sorting.

Storage

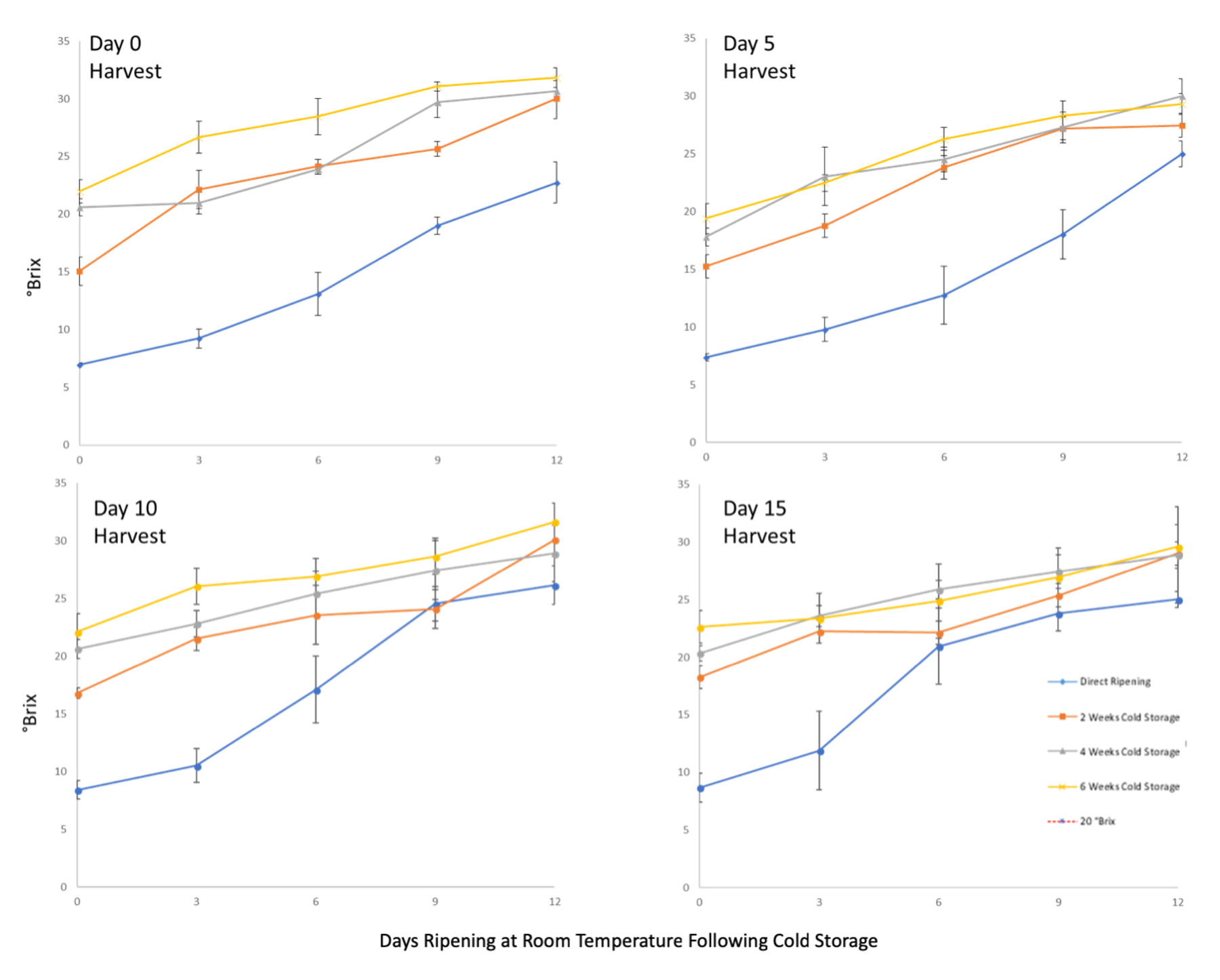

From 2016-2018, a set of basic post-harvest studies was conducted at the NHAES to determine both the expected shelf-life of kiwiberries and the amount of time required to bring berries to peak ripeness following various periods of cold storage. For these studies, berries of cultivars ‘Ananasnaja’ (USDA PI617136) and ‘Geneva 3’(USDA PI 617133) were harvested at 6-8°Brix, manually sorted, packed into 6 oz. vented plastic clamshell containers, and stored in non-ventilated, walk-in apple coolers (fluctuating 1-5°C with no relative humidity or ethylene control).

|

*NOTE: Initial reporting of these studies listed the cultivar as ‘Michigan State SVF’ due to sourced nursery tags. Subsequent genetic analysis revealed that, in fact, it was a mixture of ‘Ananasnaja’ and ‘Geneva 3’ berries used in those studies. |

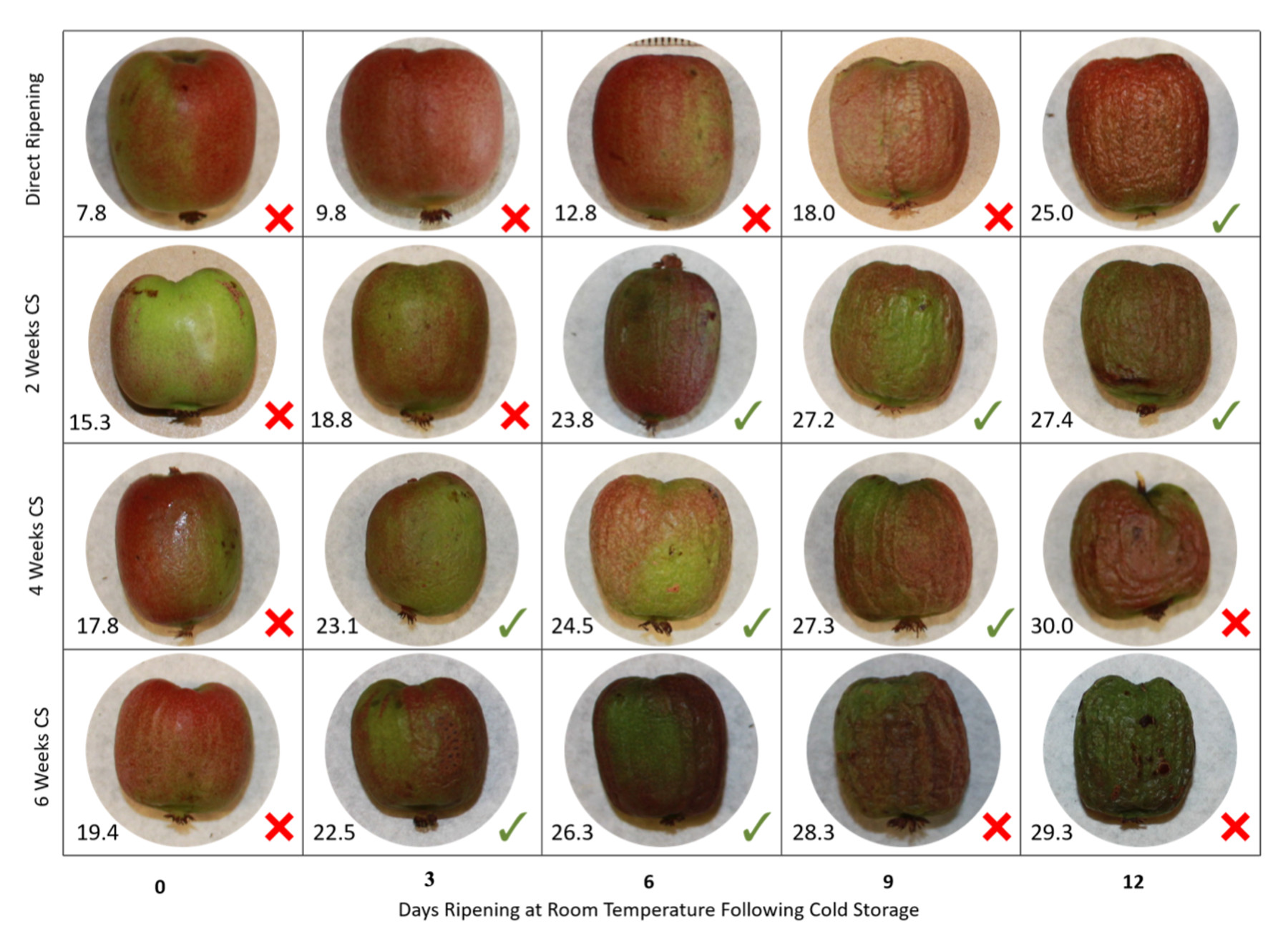

Even with this minimal control of environmental conditions, data collected over three growing seasons indicated that a mix of ‘Geneva 3’ and ‘Ananasnaja’ kiwiberries can be held for six weeks with no noticeable impact on appearance or eating quality (Fig 46). Subsequent observations have indicated that ‘Geneva 3’ may actually be held for as much as 8 weeks, with proper sorting. In contrast, depending on the year, berries of ‘Ananasnaja’ can exhibit a rapid decline in quality after only 4 weeks in cold storage. With more precise temperature control and maintenance of high relative humidity, reliable storage of up to two months can reasonably be expected for ‘Geneva 3’. Research is needed to determine the additional extension of shelf-life and post-harvest performance that may be achievable via controlled atmosphere (i.e. ethylene scrubbing and O2/CO2 regulation), though investment in such facilities (Fig 47) may not be viable for small-scale producers.

Both fruit maturity at the time of cold storage and the storage conditions themselves can significantly affect post-ripening physiochemical, nutritive, and sensory qualities (Fisk et al. 2008). High levels of oxygen and ethylene gas, low-temperature injury, and possible microbial effects have anecdotally been associated with reduced eating quality (R. Guthrie, pers. communication). To maximize storability, kiwiberries should be removed from the field at the time of harvest, rapidly cooled (e.g. via forced air), and immediately sorted, packed, and placed in conditions of consistent cold temperature (1-2°C) (Strik & Hummer 2006) and high relative humidity (90-95%) (Fisk et al. 2008). The berries should be free of excess moisture and packed in clean containers and bins that allow adequate ventilation for gas exchange (e.g. clamshells; Fig 48), thus limiting the buildup of ripening-promoting ethylene gas.

In addition to the general best practices outlined above, the results of other post-harvest studies suggest that the use of ethylene inhibitors and/or edible coatings may further enhance storability. For example, the ethylene inhibitor 1-methlycyclopropene (1-MCP) has been shown to be effective in reducing weight loss in storage as well as improving visual appearance (Fisk et al. 2008); and chitosan-based coatings can reduce instances of fungal diseases (Strik & Hummer 2006). When paired with vented clamshells, such coatings have been reported to significantly extend the shelf life of kiwiberry fruits (Fisk et al. 2008), suggesting that further research into such practices is warranted.

Pre-cooling fruit and other easy improvement to your cold storage

To maximize storability and the efficiency of your refrigerated cooling system, it is best practice to remove the bulk of the field heat from your harvested kiwiberries as quickly as possible without damaging the fruits. An efficient way to achieve this is with a simple pre-cooling tunnel, either in the cold room itself or in an intermediate, relatively cool location. Other additions to your formal cold storage area, such as plastic door curtains and small circulating fans, have proven to be effective and lost-cost improvements to the NHAES cold storage facilities; and monitoring relative humidity via a sling psychrometer is always a good idea. The University of Vermont’s Extension service has useful resources relate to prechilling and other cold storage improvements (see Appendix I ‘Grower Resources’). |

Ripening

While ripening of kiwiberries can be achieved via the regulated introduction of exogenous ethylene gas (Strik & Hummer 2006), the controlled atmosphere facility required for such a method is likely beyond the reach of small producers. In practice, ripening is as simple as allowing a container of kiwiberries to sit at room temperature for several days, while the berries respond to their own production of ethylene gas in the presence of oxygen. Here, however, a fundamental question arises: Who should do the ripening, the producer or the consumer?

While ripening can be undertaken by a producer in the hope of providing ready-to-eat fruit at points of sale, studies at the NHAES indicate that the rate at which ‘Ananasnaja’ and ‘Geneva 3’ berries reach peak eating quality varies within a clamshell and strongly depends on the stage of maturity at the time of storage, the time spent in cold storage, and the ambient conditions both in storage and during ripening (Fig 49). In other words, a reliable protocol for achieving containers of berries at uniform peak ripeness may not be possible; thus to instill such an expectation in consumers runs the risk of creating dissatisfaction.

Alternatively, taking advantage of the fact that the kiwiberry is unfamiliar to most people, there is an opportunity to educate consumers from the beginning that the berries are meant to be ripened on the kitchen counter at home, similar to bananas, avocados, peaches, plums, pears, figs, and other familiar fruits. In this scenario, dissatisfaction is avoided because consumers are explicitly disavowed of any expectation of uniform ripeness. Of course, consumers must be instructed about how to recognize peak ripeness when it occurs; and growers may wish to pull product from cold storage a few days before market in order to reduce the total length of time a consumer must wait for the berries to achieve their desired level of ripeness.

A final comment: So much to learn!

This evolving production guide is an attempt to bring into one place practical, reliable, up-to-date information on kiwiberry production. Thanks to the decades of investigations of people from all over the world, we know enough about the commercial cultivation and post-harvest handling of this novel crop to make an informed go of it; but it is clear that many unanswered questions remain (e.g. see Appendix VI ‘Areas of needed research’). With an expanding regional network of collaborative producers and increased investment in research, however, we can continue to make progress in these areas. |